Pellet fuel is made of sawdust, crop straw, rice husk, peanut shell and other agricultural or forestry residues.

It is compressed into rod-shaped, granular and solid shaped pellet fuel by the physical method of pellet machine.

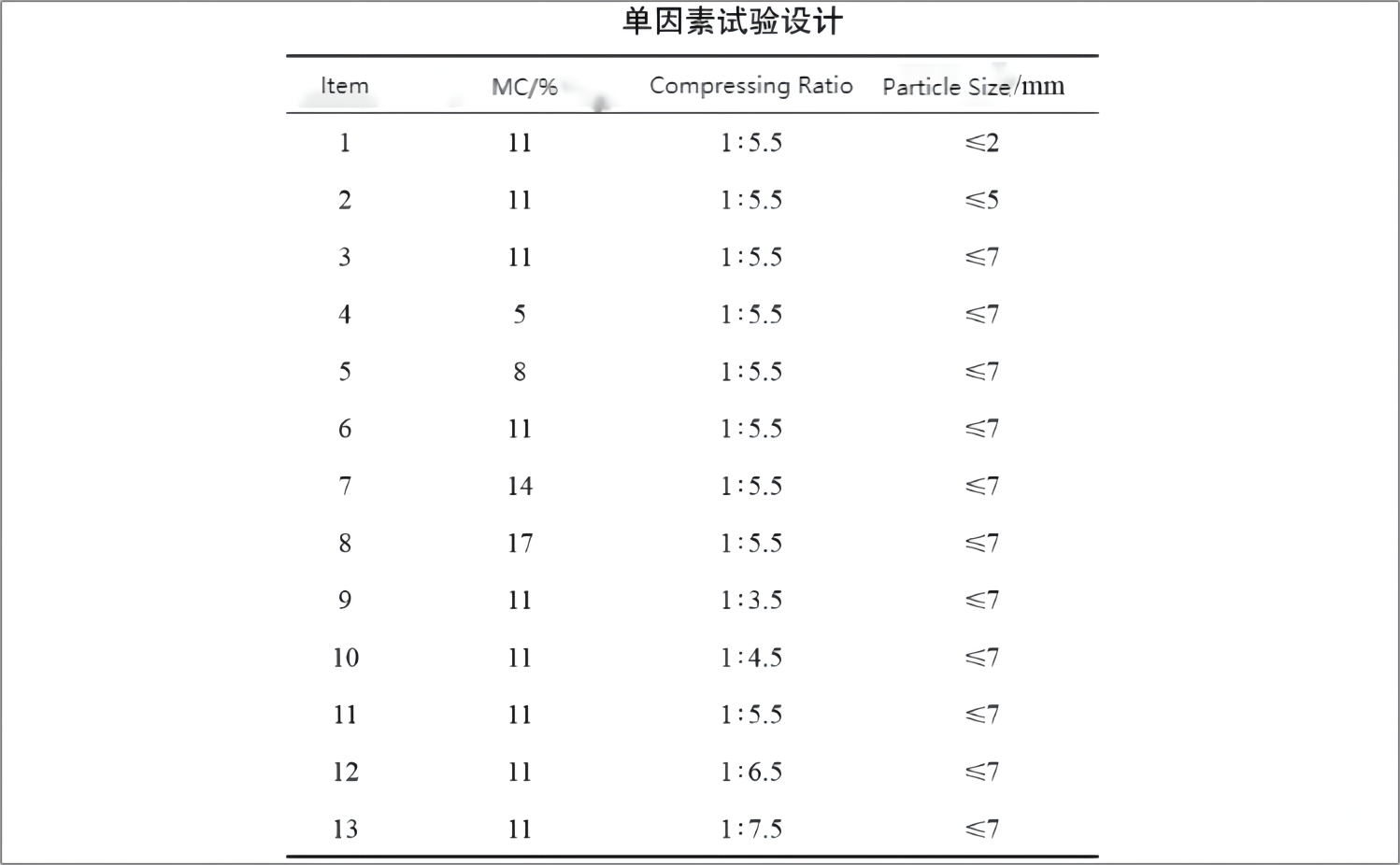

During production, the operators may find that sometimes the pellets are not formed as expected. Experienced masters know that the moisture content of the raw material, the compression ratio of the ring die, and the particle size of the raw material may affect the pellet forming rate and density. Today we will give an example to briefly talk about the most suitable moisture content of the raw material of rice husk.

Raw material moisture content test of rice husk pellet.

A research team selected rice husks with a diameter of ≤7mm as the experimental material, and used the MUZL420 model granulator as the experimental conditions to conduct experiments with different moisture contents and ring die compression ratios. Each level was repeated 3 times, and the average value was taken.

It can be seen from the figure below that when the moisture content of the raw material is 5%, the particle forming rate is 0, and when the moisture content of the raw material reaches 8%, the forming particles begin to be produced, and then with the increase of the moisture content of the raw material, the forming rate of the product increases greatly. ; When the moisture content of the raw material reaches 11%, reaching a peak value, and then with the increase of the moisture content of the raw material, the molding rate of the product decreases greatly; when the moisture content of the raw material reaches 17%, the molding rate of the granular product drops to 0 again. When the moisture content of the raw material is 8% and 14%, although the raw material can be formed, the forming effect is poor and the forming rate is low.

This shows that the moisture content of the raw material has a great influence on the forming rate of the rice husk particles. Appropriate moisture content helps the softening and bonding of the lignin in the rice husk raw materials, promotes the formation of chemical bonds such as hydrogen bonds in the rice husk raw materials, and It is beneficial to the lubrication between the rice husk raw material and the ring die during compression molding; however, if the moisture content is too high, the moisture will form tension in the raw materials and expand the gap of the raw materials, thereby increasing the repulsion in the raw materials, hindering the contact between the raw materials, reducing the the intermolecular force and reduces the forming rate significantly.

Through experiments, we can know that the moisture content of raw materials has a significant effect on the forming rate of granular products. This time, the compression ratio of the ring die is 1:5.5. Considering factors such as energy consumption, production efficiency, product cost and product quality, the optimal moisture content is 11%-12%.

Different raw materials, different machines, and different production processes have corresponding changes in the appropriate moisture content of raw materials. In addition, factors such as energy consumption and production costs should be fully considered. The moisture content of common raw materials is mostly 11%-18%. If the moisture content is too high, when the raw material enters the ring die, it will block the die hole, so that the pellet cannot be produced; if the moisture content is too low and too dry, It is not easy to form, and the viscosity is not enough, which affects the quality of the pellet.