The opening rate of the pellet ring die directly affects the production capacity of the pellet mill.

The higher the opening rate, the more output is discharged, which is beneficial to improve the productivity, but the thickness of the wall between the die holes becomes smaller, the strength of the pellet die decreases, and it is easy to crack, and at the same time, the friction is reduced, and the temperature is relatively lowered.

Pellet die hole opening rate calculation method:

Opening rate = Sum of hole area (M)/Total working area (N)

M=Number of holes×π(d/2)²

N=K×πR

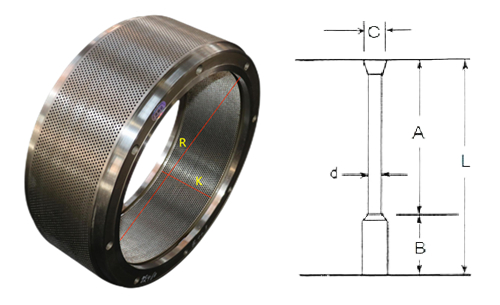

d=effective pressing hole diameter (as shown in the figure)

K=Working area width (excluding the grooves on both sides and the width of the non-working area outside the grooves, as shown in the figure)

R=Inner diameter of ring die (as shown in the figure)

Here we also indicate the pellet die compressing ratio calculation method:

Compressing ratio=Effective Pressing Stage/Effective Pressing Hole Diameter

Compressing ratio=A/d

L=Total thickness of pellet die

A=Effective Pressing Stage

B=Relief Stage