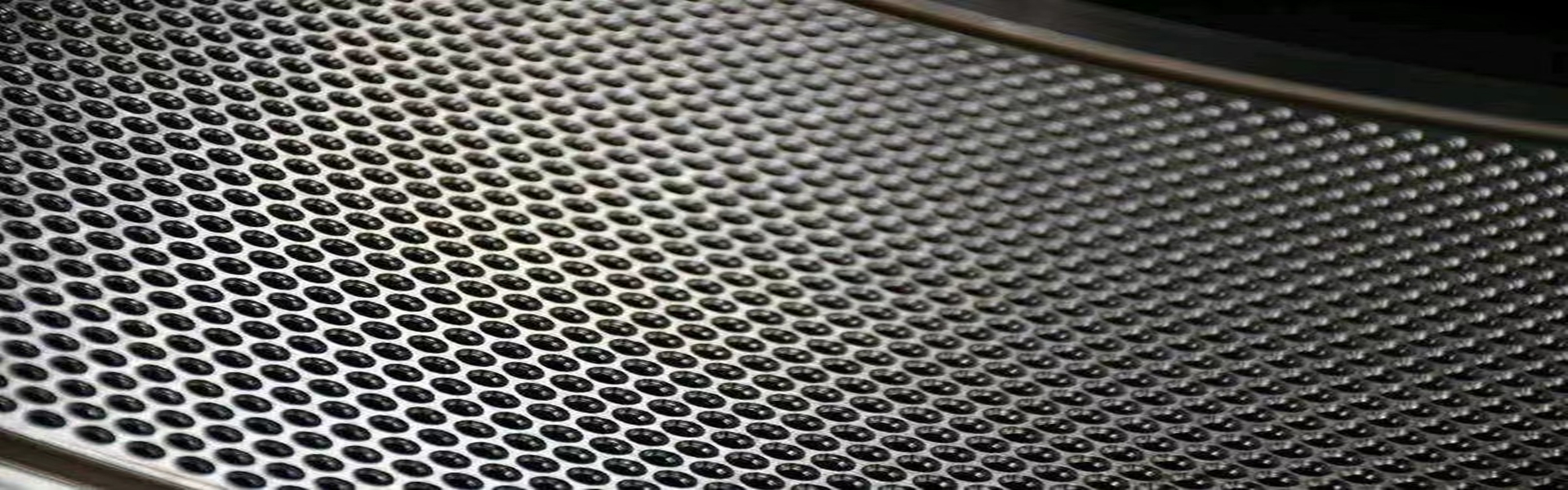

There are many reasons for causing pellet die /ring die break, here below some reasons for your reference:

1. Pellet Ring die material

The material used for the pellet die is one of the important reasons.

The selected pellet die material is not suitable for the operating conditions and working conditions of the die.

Right now, China pellet die mainly use 4Cr13 and 20CrMnTi, which are relatively stable. It's just that the manufacturers of raw materials are different, and there will be certain gaps in trace elements for the same materials.

2. Pellet die Forging process

This is an important link in the pellet die manufacturing process, and irregular processes can easily lead to cracks in the ring die blank. For alloy steel molds, the forging temperature range should be strictly controlled, correct heating specifications should be formulated, correct forging methods should be adopted, and slow cooling or timely annealing after forging should be adopted.

3. Ring die Heat treatment

If overheating occurs during quenching and heating, it will not only cause greater brittleness of the workpiece, but also easily cause deformation and cracking during cooling, which will seriously affect the life of the mold. After quenching, it should be tempered in time, and different tempering processes should be adopted according to technical requirements. In addition, the mould should be subjected to stress relief annealing treatment after rough machining, in order to eliminate the internal stress caused by rough machining, so as to avoid excessive deformation or cracks caused by quenching.

4. Ring die design

The opening rate of the ring die is too high, the thickness is too thin, and the strength decreases, which will also lead to the phenomenon of pellet die cracking in production.

5. Ring die wear

When the pellet die is worn to a certain thickness and the strength is reduced to a point where it cannot withstand the pressure of granulation, cracking will occur. It is recommended to replace the ring die in time when the ring die is worn until the groove of the pressure roller is flush.

6. Pellet die Installation and use

The gap between the ring die and the pressing die roller is too tight, and it is easy to cause cracking and explosion of the pellet die.

Generally, we require that the gap between the ring die and the pressing roller should be controlled between 0.1-0.5mm. In addition, in the granulation process of the ring die, the amount of material entering the pellet die cannot be operated at 100% load because of the high granulation output of the ring die itself. Such a long-term high-intensity operation will also lead to cracking of the ring die. It is recommended to control at 75-85% of the load to ensure the service life of the pellet ring die.

7. Metal impurity

When hard objects such as iron blocks appear in the granulated material, it is easy to cause the pellet die to crack. If the pellet die is cracked, it must be replaced, otherwise, it will be a joke with the operator's life, and people will be killed or injured.