1. Characteristics of raw materials

Generally speaking, pine wood and other relatively soft wood sawdust are more easy to granulate, if the raw material texture is excellent, or the raw material is flour-shaped fine powder, it is recommended to add shavings, basically can be formed, please note that the basic forming, that is to say, there will be short forming particles. Under normal circumstances, the raw material requirement of the pellet machine is through the 6-12mm hole diameter grinder screen material, that is, about 1-5mm sawdust.

2. Pellet die compressing ratio

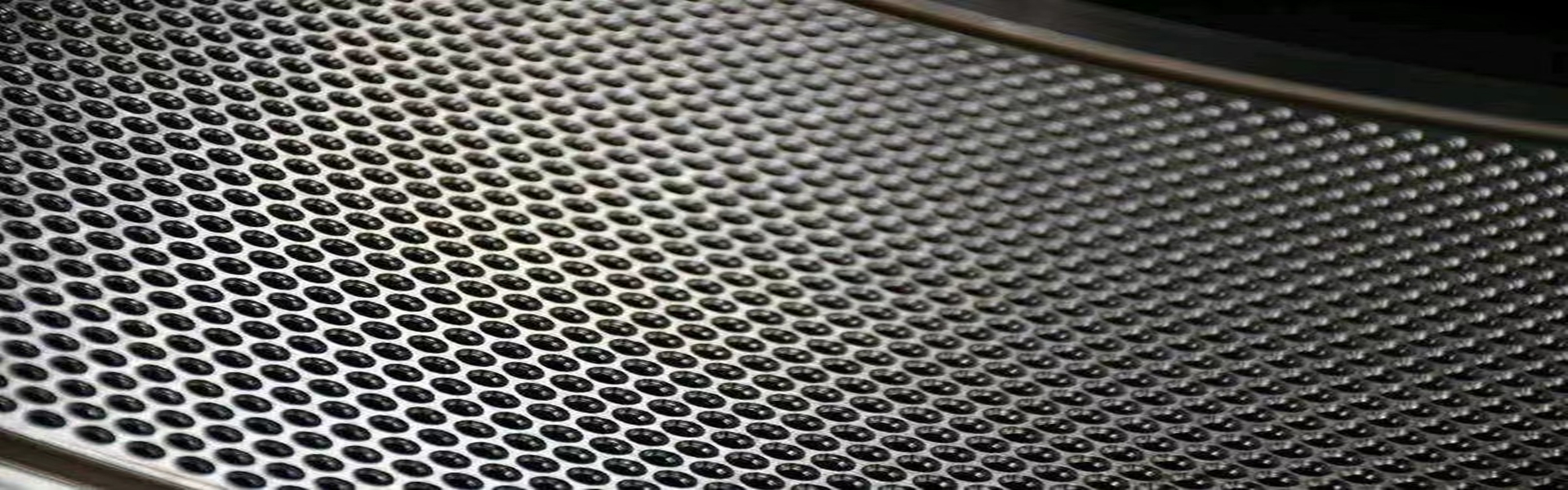

Different materials need different compressing ratio moud, if the pellet die is blocked, or the pellet are shiny, and even with carbonization black surface, or pellet is soft, loose, powder, that means the ring die compressing ratio is not suitable for the production of current materials.

3. Gap between roller and pellet die

The suitable gap between the roller and ring die is 0.1-0.3mm. If the gap is too large, the pressure is not enough to squeeze and form the pellet. If the gap is too tight, it will damage the ring die.

4. Raw material MC.

The water content of raw material is also the key to the pellet forming. The uneven moisture of raw material, too dry or too wet will lead to the blockage of the pellet die hole, resulting no output. Generally speaking, the suitable MC of the material for making biomass pellet is around 13% -17%, but this data is not fixed always.